Throughout the first trimester, Upper School Science Teacher Mr. Travis Menghini’s robotics class applied what they’ve learned to a real-world application by building bridges. Their bridges had very strict parameters, and the students excelled within their limits. (Check out our fun slo-mo video of bridge testing at the end of this article!)

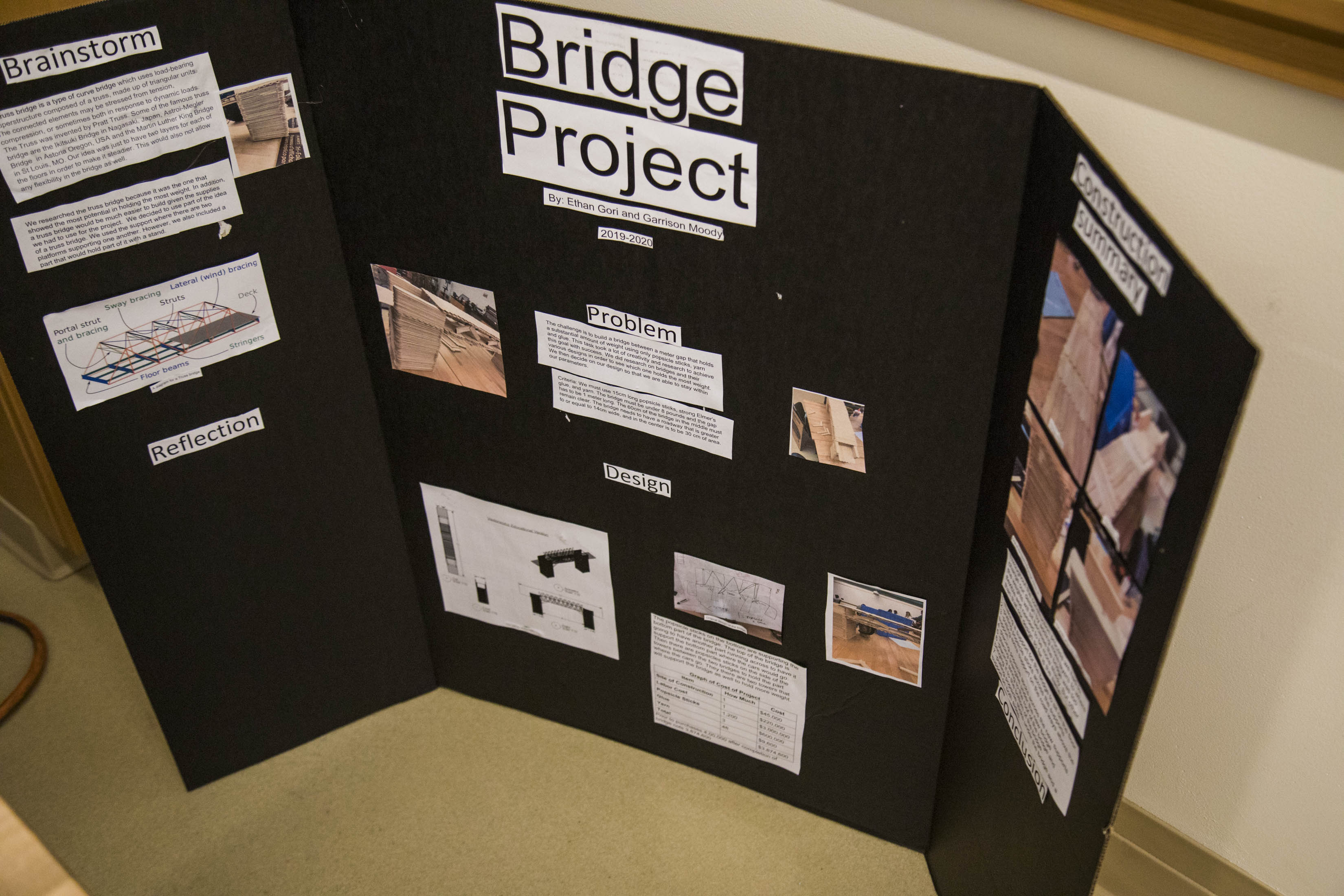

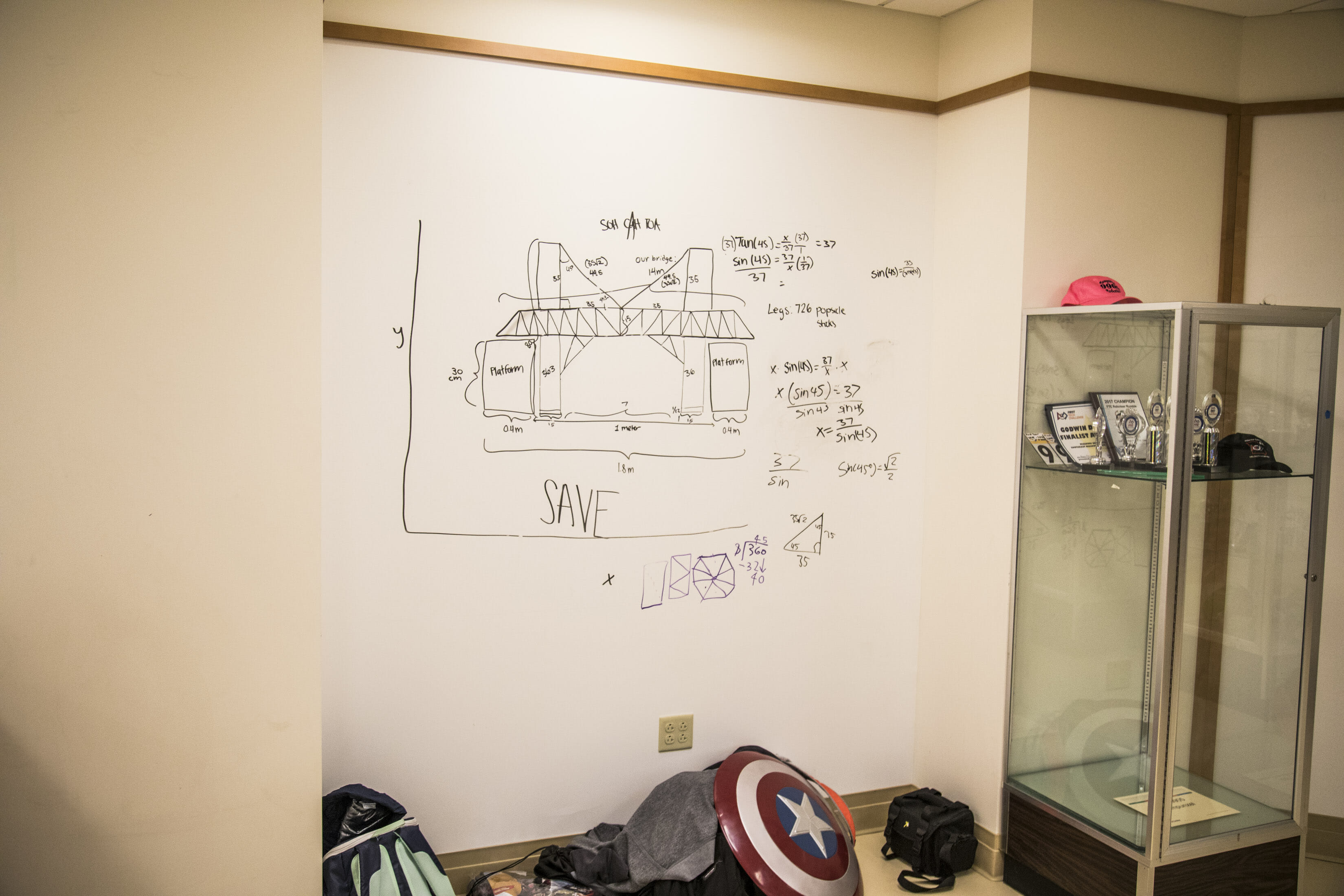

Initial goals included ensuring each bridge spanned one meter long with supports at only 20 cm on either end. The six teams had to research, brainstorm and design their bridges in a CAD program before actually building them. Each team researched various well-known bridge designs—such as truss, suspension and arch—before starting their plans.

At the end of the project, the bridges were tested on their strength static load (weights) in addition to their strength/weight ratio (Live Load in lbs ÷ Bridge Weight in lbs).

Mr. Menghini explained, “It’s the responsibility of the engineers to ensure that their bridge design is safe. One measure of a bridge’s safety is to determine the maximum live load that the bridge can support. In general, most people prefer an attractive, creative and inspirational bridge design. If a bridge is strong but unattractive, that design will most likely not be selected over other, more creative designs.”

Here are some of the design parameters:

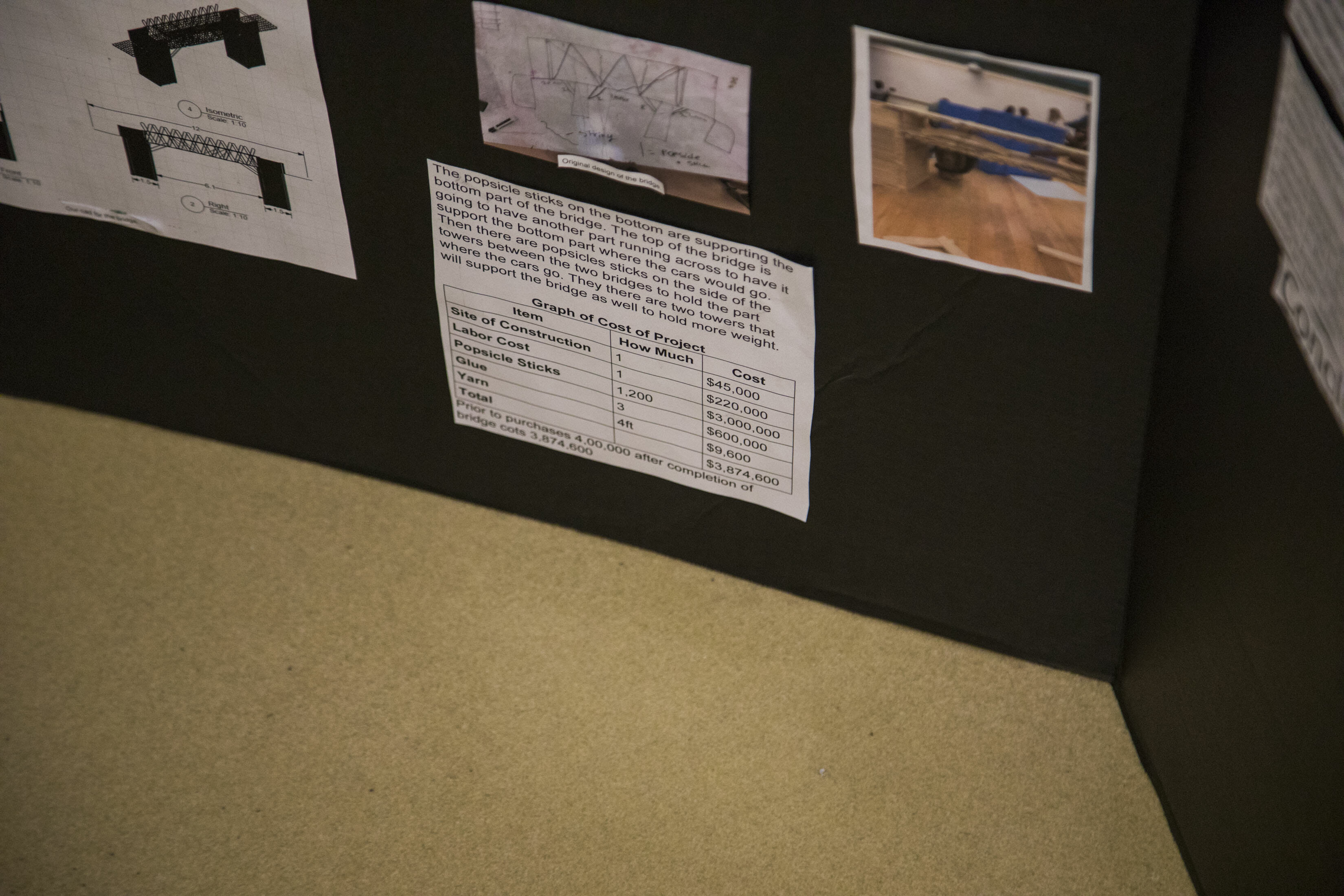

- Students could only use Elmer’s Glue, yarn and popsicle sticks.

- Each team had an unlimited budget with materials, labor and the site of construction each having a cost associated. They were required to estimate their project costs and report it compared to their final actual costs, along with an explanation of the difference. (Most of the time the difference was due to popsicle sticks being broken out of the box!)

- The bridges had to be at least 100 cm in length. The supports in the middle could not be closer than 20 cm on each side.

Several teams reported that they ran into time-management issues after choosing one bridge design and then realizing throughout the project that material limitations prevented them from moving forward. For example, while an arch bridge may have sounded like a good idea, teams learned that popsicle sticks can’t easily be bent to create an arch shape.

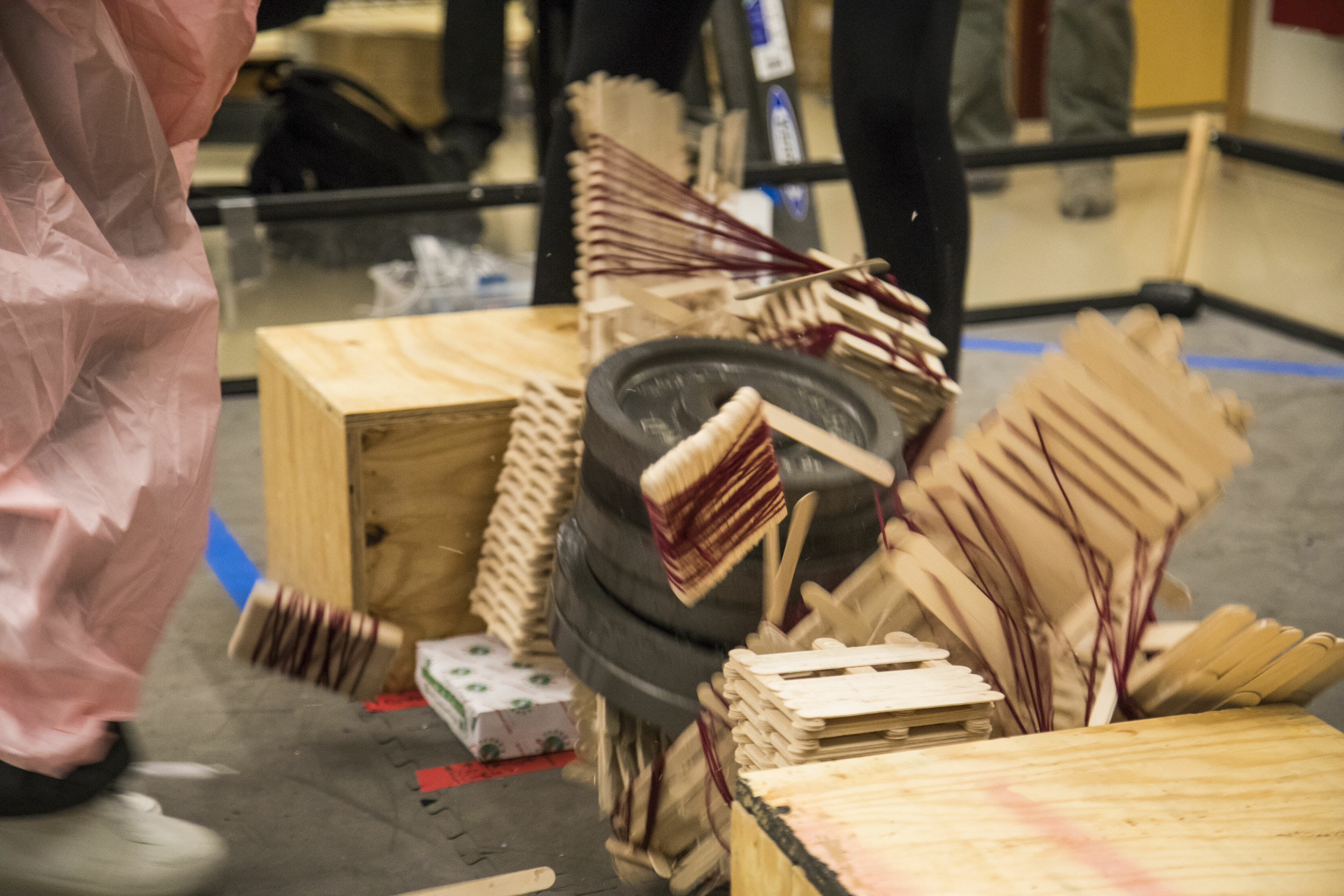

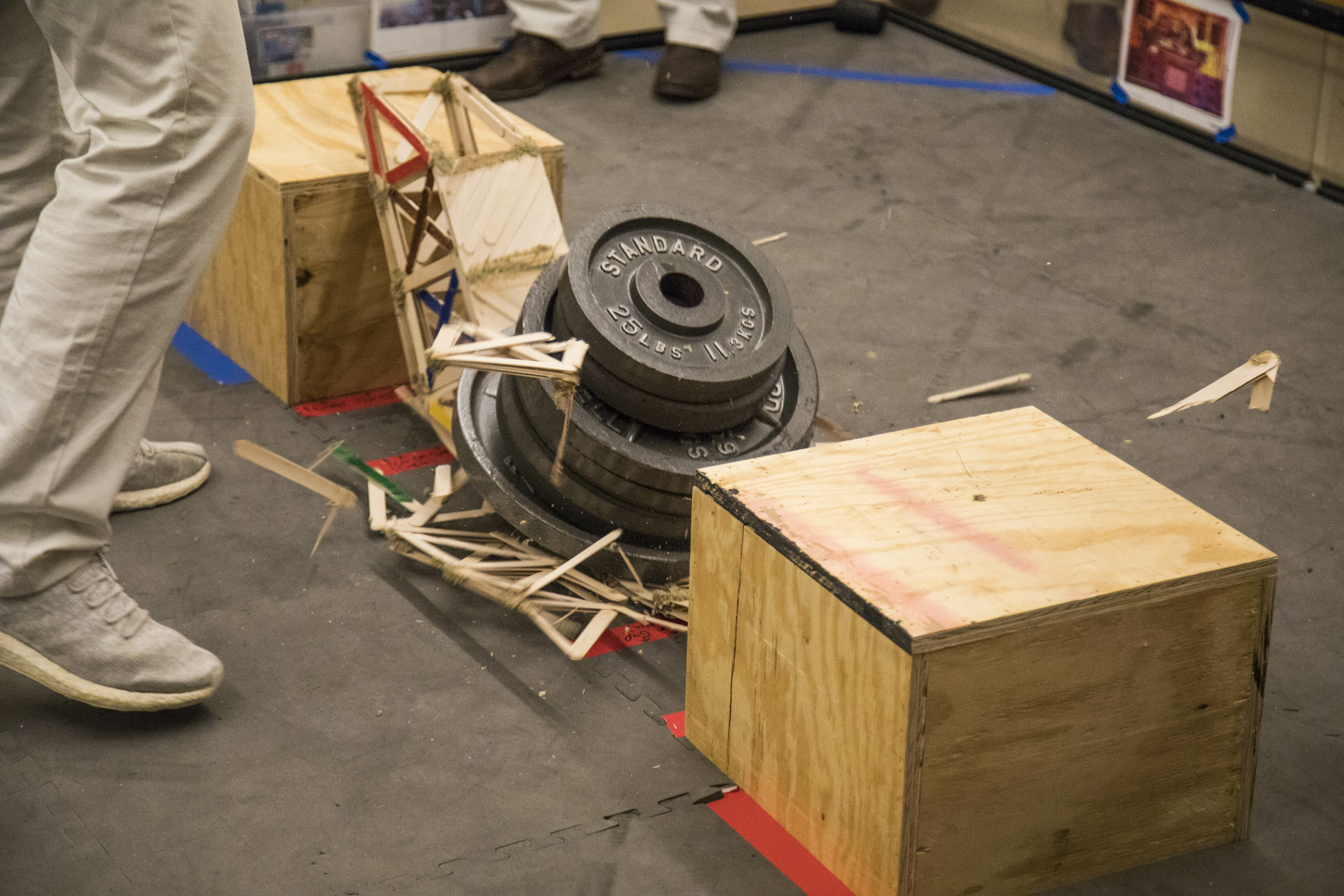

Each completed bridge was put under a stress test using barbell plates. Not only were the bridges being tested on how much weight they could hold, but also how much weight the bridge could hold in comparison to the overall weight of the bridge. The better the ratio (lightness in materials to weight it could hold), the better the bridge. Some of the teams came up with creative project backgrounds, such as reconstructing a bridge due to an earthquake in the Portland, Oregon area or creating a bridge for heavy mutant ants to cross a river. They learned that it’s important to understand exactly what you’re building your bridge for (pedestrians versus coal trains, for example) in order to maximize materials.

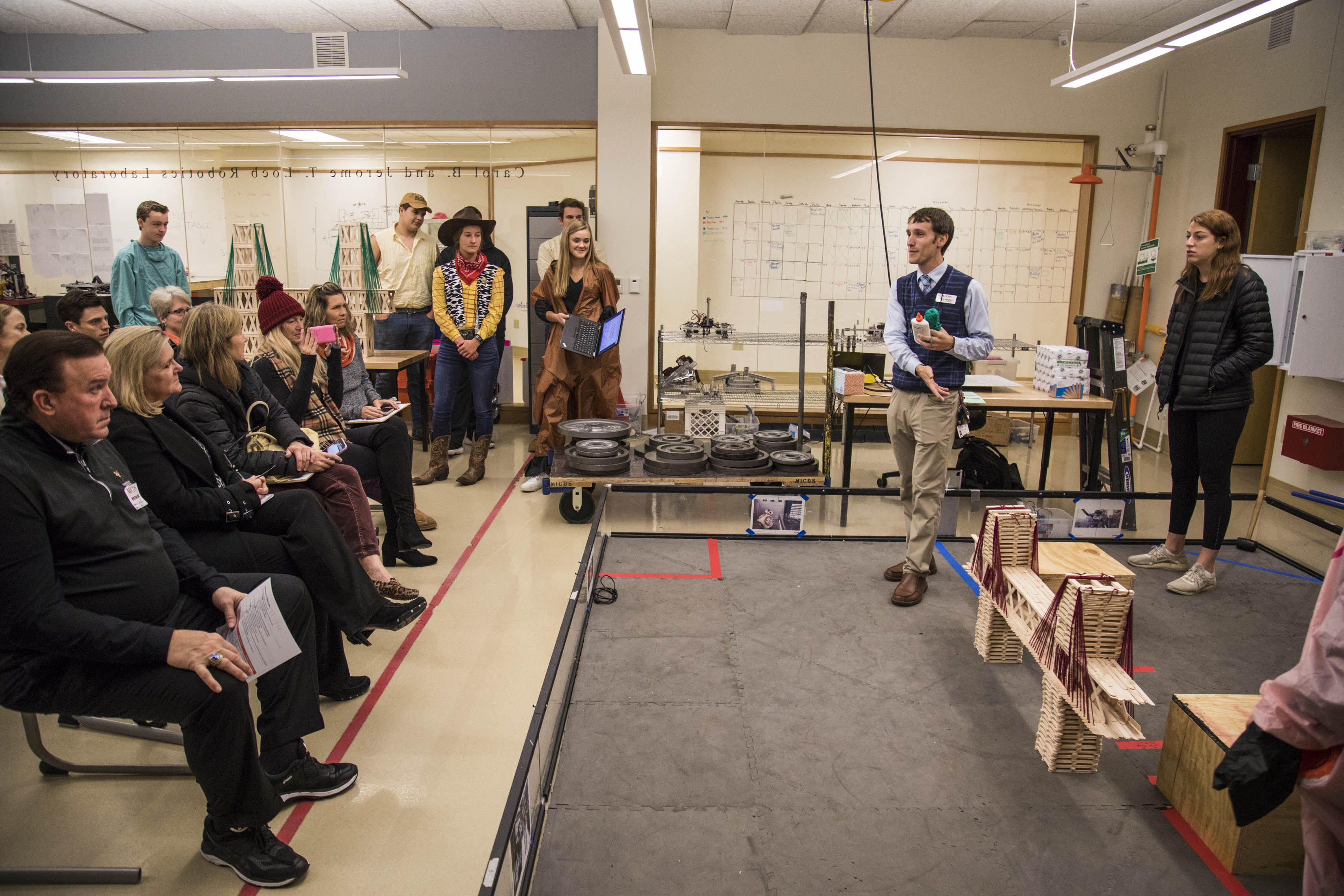

Parents, staff and faculty were invited to inspect the bridges and guess how much weight they could hold before each team gave presentations on their bridge and performed the stress test. (Stress tests were performed on Halloween when our seniors dressed in costumes for the afternoon assembly!)

Students added weights in increments until the bridges broke, with some bridges holding a tremendous amount of weight. After the stress tests, students analyzed where, how and why their bridges failed. Nearly all the teams cited torsion issues within their designs.

To complete the project, students presented their processes and results to their peers and reflected on what they’ve learned. Lauren Mishkin ’20 said, “We could have made our bridge much lighter and stronger. We spent a lot of time on the legs, making sure they were sturdy. They held much more weight than the bridge itself, but they made our whole bridge heavier. By brainstorming, design and constructing, we learned many lessons on teamwork, CAD, construction and engineering elements. We overcome adversity by using trial and error, and we learned how to properly support more weight and create a more durable bridge. This project taught us many lessons we can apply to other classes.”

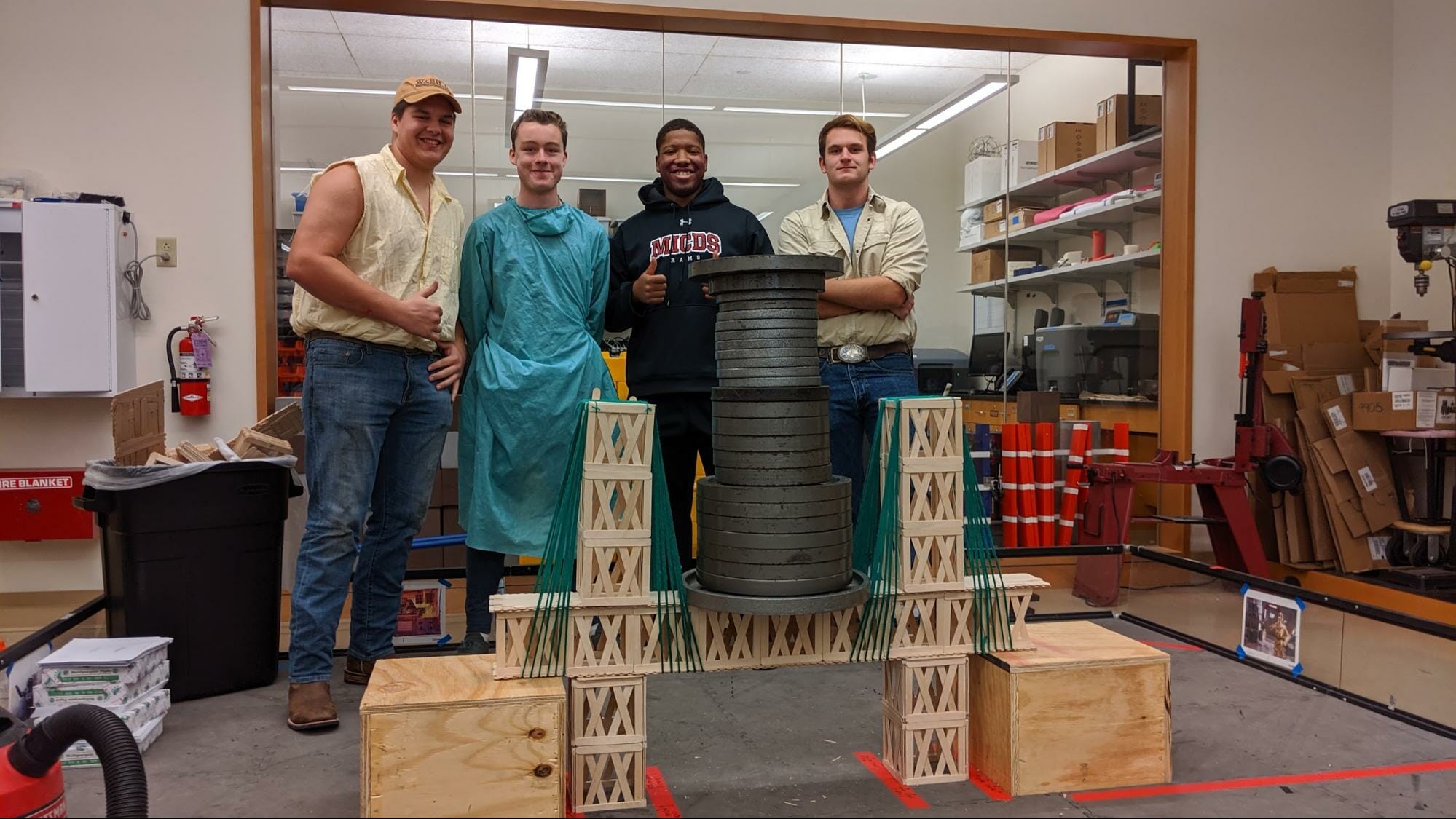

Gerald Bentley ’20 enjoyed the project. He talked about how he was surprised by the amount of weight the bridges could actually hold. “When Mr. Menghini first introduced the project, we thought maybe the bridges could hold 80 pounds, which doesn’t seem like a lot of weight.” The students watched a video of a bridge-building competition and realized there was enormous potential. “I liked that we can use simple materials to make complex bridges that hold a lot of weight!”

Jack Bay ’20 agreed. “I was surprised by the notion that more isn’t necessarily better.” His team had used stacked popsicle sticks to create their bridge’s legs, and upon reflection realized “we could have made lightweight structural frames that would have worked better and weighed less.”

Mishkin’s team also learned a lot from their competitors. She said, “We could have made our bridge so much more effective but lighter if we would have used little squares as some of the other teams did. We could have made our bridge 10 times lighter and 10 times stronger.”

Congratulations to the team of Jack Bay ’20, Gerald Bentley ’20, Jack Parks ’20 and Dean Sliney ’20, who won the competition with a bridge that weighed 9 lbs .2 oz, held a whopping 635 lbs and had a weight/load ratio of 70.5!