Did you know that MICDS now boasts three fully functioning and well-equipped makerspaces? At the start of the school year, Chief Information Officer Stewart Crais met with a focus group that evaluated the Maker Program at MICDS. The group came up with a strategic plan for launching the brand new Lower School Makerspace and revitalizing the current Middle and Upper School Makerspaces—and what a treat for students! From Junior Kindergarten through 12th grade, students can be seen digitally fabricating, building, and constructing their own self-made creations.

Much of the funding for this project was generously supported by CDS alum Jack Thomas ’70. Thomas gave a donation as part of his 50th reunion gift to the Head’s Discretionary Fund which allowed Head of School Jay Rainey to direct the support as needed to this project.

New equipment has continued to arrive throughout the school year, but for now, check out just a glimpse of the makerspace action across the MICDS campus!

The Grand Opening of the Beasley Makerspace

This past fall, the Lower School transformed a classroom into the new Lower School Makerspace. Although our Junior Kindergarten through fourth graders visited the Middle and Upper School Makerspaces in the past, they now have the opportunity to create, design, and build items of their dreams in their own dedicated makerspace.

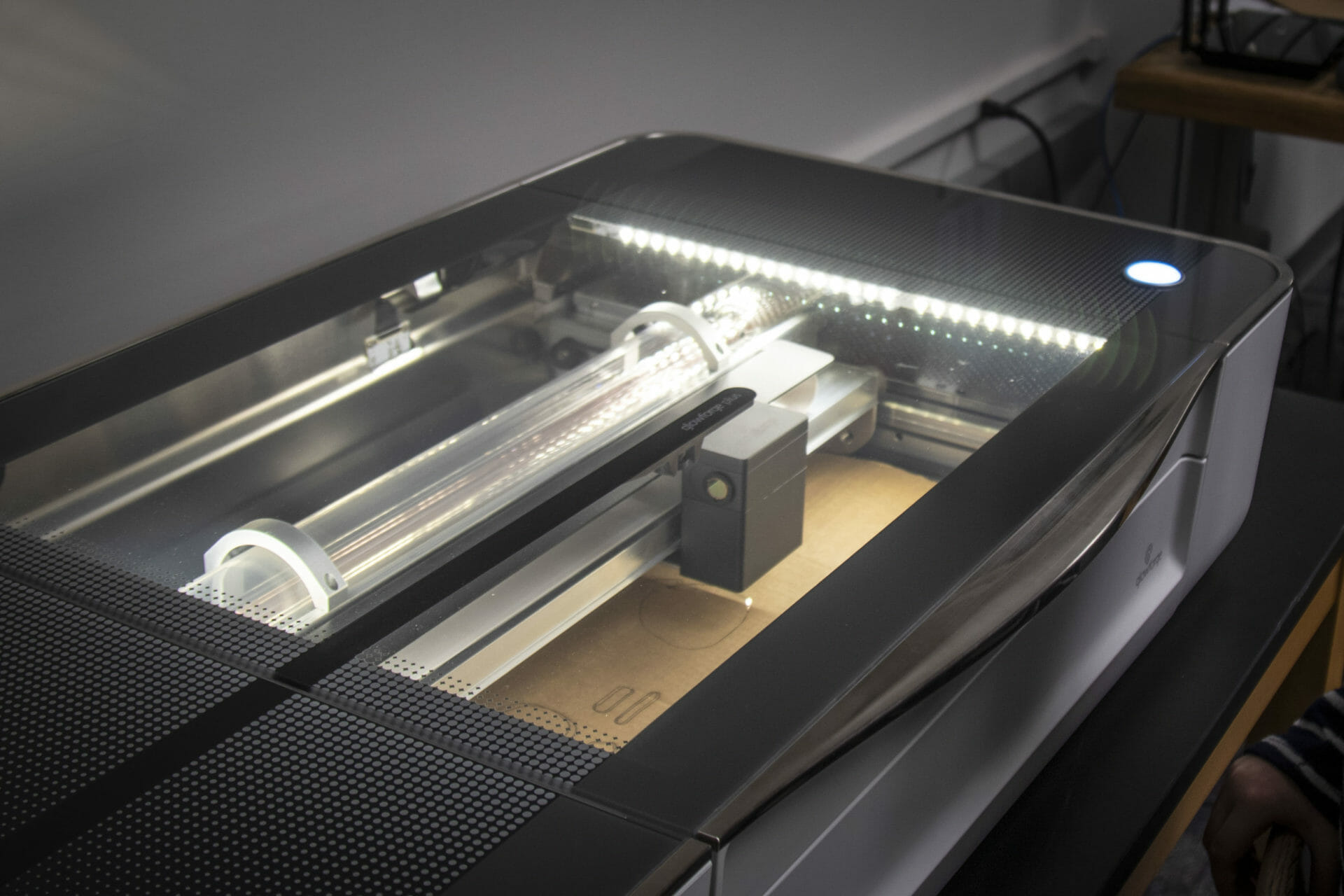

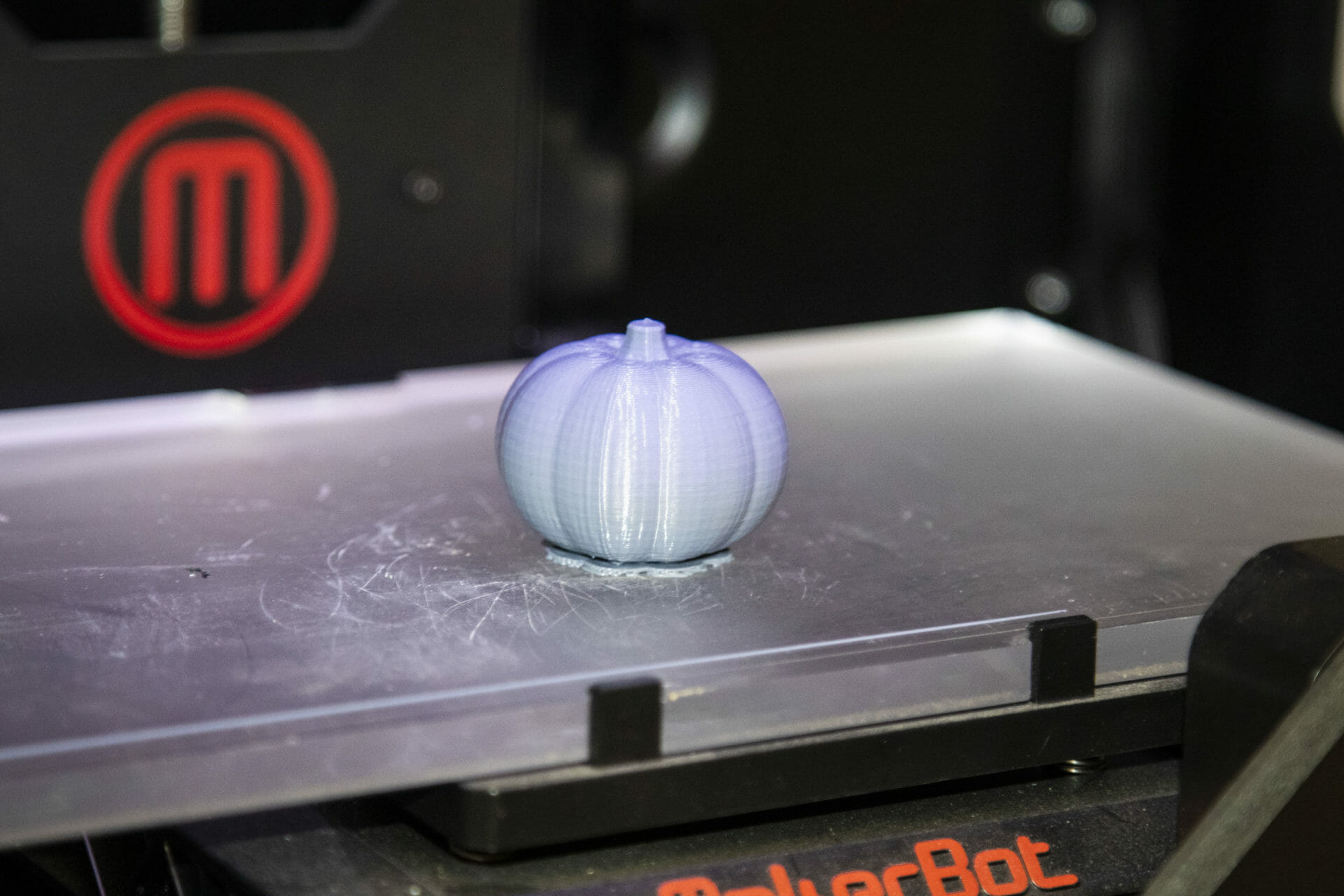

The Beasley Makerspace is home to three MakerBot 3D printers, one Glowforge 3D laser printer, a full-wall green screen for video production, and tons of maker materials. Beasley students are learning about digital fabrication, the process wherein digital data drives manufacturing equipment. They are also learning how to use the 3D printers and the green screen.

In a sample project in the Lower School, fourth-grade students created symbols to represent one of the global goals of the United Nations. They designed their symbols through KidPix, SumoPaint, or Sharpie drawings, sent the files to the Glowforge machine, and laser printed the piece on cardboard. Check out this first experience in using the newly-launched Lower School Makerspace to solve world issues!

What does the new space mean for Lower School? Greg Stevens, Lower School Coordinator of Instructional Technology, said, “The Makerspace is a multi-purpose room that welcomes teachers and students who come to meet, collaborate, and learn the use of innovative tools. It offers a tremendous opportunity that we are just beginning to explore!”

Middle School Makerspace Makeover

Four years ago, the first iteration of the MICDS Middle School Makerspace was built. The area was used partly as a makerspace and partly as a science classroom. It also had a packed storage closet filled to the brim with science materials. Then the pandemic hit in March of 2020 and the room was converted into a full-time classroom. Using the space this way allowed for instruction with students spaced adequately as required by health and safety guidelines. Although there was a hiatus from the makerspace, Middle School Maker Coordinator and Science Teacher Branson Lawrence used the time to completely reimagine the room. After clearing it out, organizing and upgrading the equipment and materials, and adding a few personal touches, the makerspace reopened its doors in the fall as a dedicated, full-time space for making anything students can imagine with the help of our incredible faculty and new tools.

As you walk through the doors of the makerspace, a student-created sign overhead reads “MAKE” to greet you. It’s made of cardboard and is sprinkled with nails, string, feathers, and chain links. Inside, a variety of tables fill the main room as the launchpads of creativity as students start to dream. Around the periphery of the main room are two new band saws, a drill press, hand tools, cardboard, and many other materials (i.e. Q-tips, rubber bands, beads, paint, and straws). A small, adjacent room with a window into the larger space includes a brand new X-Carve CNC (Computer Numerical Control) machine which is used to cut and carve material as programmed by digital data. Students try their hand at digital fabrication with expert guidance from Middle School Coordinator of Instructional Technology Pat Woessner as they first create a digital file on Easel, a CNC software program. Once created, they upload it to the CNC machine where their design gets carved. There’s also a project storage area with bins of student work that is in progress and a cabinet that is full of paint.

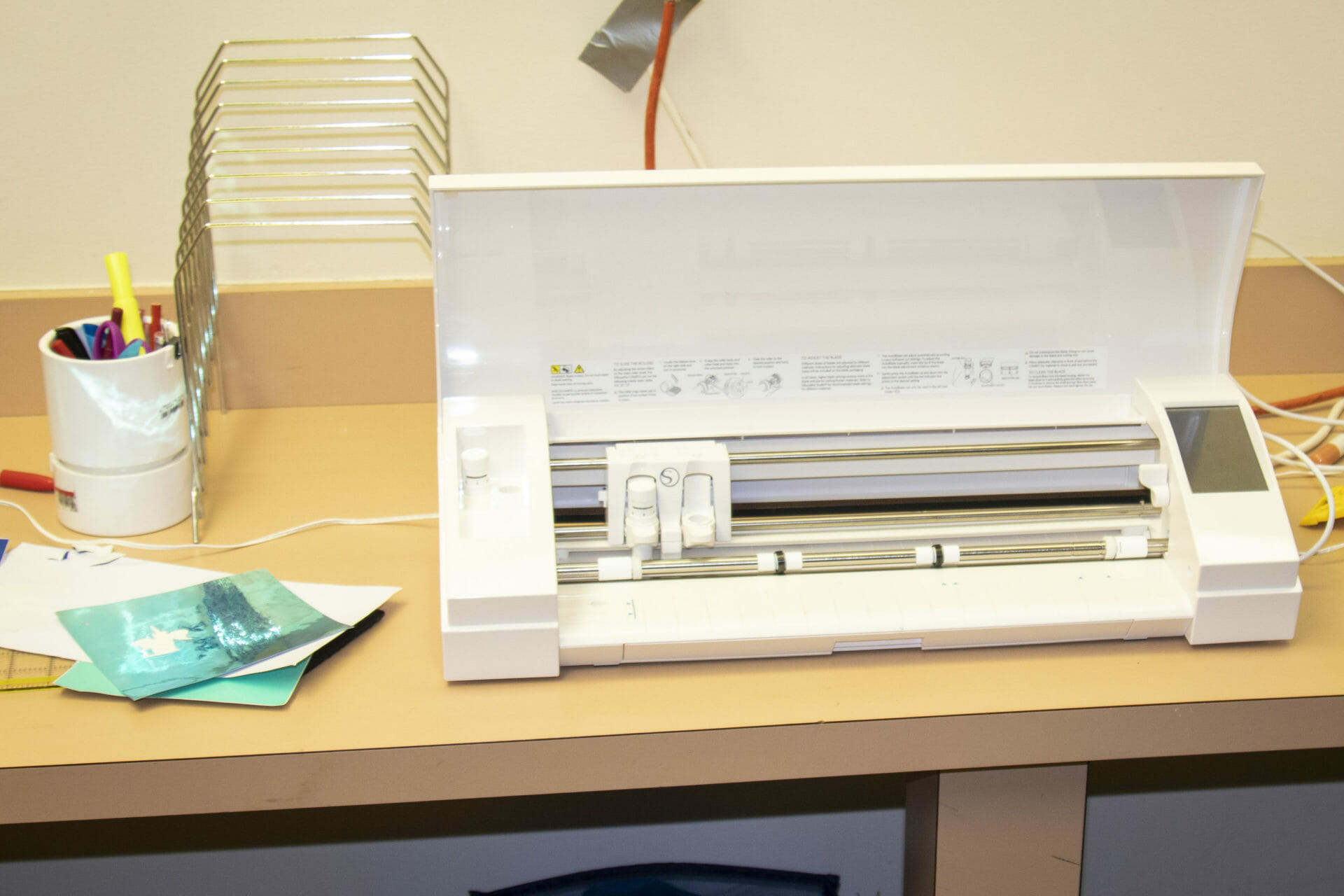

What happened to the previous storage closet? It’s now transformed to hold the new Glowforge 3D Laser Printer (this cuts and engraves cardboard), several 3D printers, a sewing and embroidery machine, and a cameo machine used to cut vinyl, paper, fabric, and other materials. This closet also has a window into the main room but is separate since these tools can’t be around sawdust.

Throughout the school year, Middle Schoolers in fifth and sixth grade visit the makerspace regularly as part of their class schedule. They decide what they want to make and our teachers guide them through the planning processes and oversee their use of the machines. There are also lessons on safety, personal protective equipment like goggles, and safety cards posted throughout the room to reiterate using each piece of equipment safely. This time in the makerspace helps fifth and sixth graders gain a basic understanding of all-things maker. Moving onto seventh and eighth grade, students have the option to visit the makerspace before and after school as well as during lunch when faculty are available.

The makerspace is also available for collaborative projects and supplementing lessons across different subjects. Students make scenes of Egypt from a snapshot in time to add to their social studies lesson, for example. They have 3D-printed pumpkins, created heart-shaped boxes out of wood, carved Darth Vader with the new CNC machine, designed their own vinyl stickers, built a chair, and three students even made a table in October that they delivered to Linda Ganss, Lower School Administrative Assistant.

Students aren’t the only ones learning through the use of the makerspace. MICDS Learning Specialists recently had fellow staff and faculty work in the Middle School Makerspace to bring the concept of Universal Design for Learning to life. Additionally, faculty members partake in professional development experiences to master new equipment to safely guide students through its use. For example last summer, Lawrence participated in a weeklong workshop at Saint Louis University to build a 3D printer, the Creality Ender 3 V2, and learn how to use and troubleshoot it. Now, that piece of equipment is in the MS Makerspace. Students make great teachers as well! Lawrence learned how to embroider “MICDS” into a piece of fabric thanks to a Middle School Ram.

Before the MS Makerspace Makeover (Photos from 2017):

After the MS Makerspace Makeover (Photos from October 2022):

Updates in the Upper School Makerspace

The Upper School Biggs Family Makerspace also received a significant amount of new equipment and new resources to allow students and faculty to embrace maker culture both in classroom experiences and in their own free time. Two new Raise 3D printers and two new Dremel Digilab 3D printers greatly increased the Upper School’s capacity to print for larger numbers of students in order to accommodate the increased demand being placed on the Biggs Family Makerspace. A 3D printer was moved to the library to accommodate Upper School makers for independent projects. A new CNC mill, a Logic Trace CNC DXF Digitizing System, an Eazao Ceramic 3D Printer, and a WAZER Waterjet printer were purchased as well as three 3D resin printers. Resin printers allow for much finer detail and work by having light harden a liquid resin according to the digital file being printed.

With more equipment, lessons and independent projects are taken to the next level in so many ways. In the fall, students in 10th-grade science used the new 3D printers to make specially-sealed caps for their own fire extinguisher creations. Sophomore science students additionally printed newly-released protein files and examined the protein structure of their printed models while using scholarly journals to understand how that structure impacted the proteins’ functions. Ninth-graders used the makerspace to build roller coasters and made measurements to understand the laws of motions and energy transformations. Maker class students learn about design thinking, and in keeping with the maker principle to “design for good,” use their skills to tackle projects that could help solve problems or enhance things on our campus. One project tasked them with designing lighting enhancements to the parking signs as requested by MICDS Security. Students in plant science electives researched the many plants on campus and created informational signs in the makerspace. They then moved on to the MARSfarm project in which they explored ways to improve the ability to grow plants on Mars using a growth chamber modeled after the ones NASA uses. For this project, students used Arduino, a company that builds single-board microcontrollers, to program lights and heat in addition to measuring oxygen and carbon dioxide production. To assist in their experimental methods, they printed 3D parts as needed. The design for good principle is also being explored as students consider the feasibility of printing supplies like periscopes and stethoscopes for Ukraine. As with the projects that students did during the COVID-19 pandemic, there are many obstacles with regard to supply chains and specifications that make the equipment technically sound.

Cross-divisional maker action is also always booming. In March, the Upper School space once again welcomed third-graders for their annual game-making projects. Third graders, assisted by Upper School faculty and students, laser-engraved wooden game boards, 3D-printed playing pieces, and built spinner dice poppers and sand timers using a variety of maker equipment.

Another key maker principle is that makers share. To that end, Coordinator of Pedagogical Innovation Elizabeth Helfant, Upper School Maker Coordinator Brian Purlee, and JK-12 Science Department Chair Paul Zahller will be traveling to Woodward Academy in Atlanta to host a workshop where they will assist Woodward Academy in their understanding of the many ways maker can be utilized in the curriculum.

Thank You, Makers and Maker Supporters!

Thank you to all who helped open the doors this year to the Beasley Makerspace and supported the upgrades of our existing makerspaces. For other updates in our makerspaces, check out the MICDS Makerspace website, managed by our Maker Coordinators. Thank you also to all who help run the makerspaces so safely and creatively. These changes have made learning throughout every grade at MICDS even more profound.

What would you make in any of these three makerspaces? The possibilities for MICDS students, faculty, and staff are endless!